Introduction

Foundation: 1973

Location: Taichung Plant

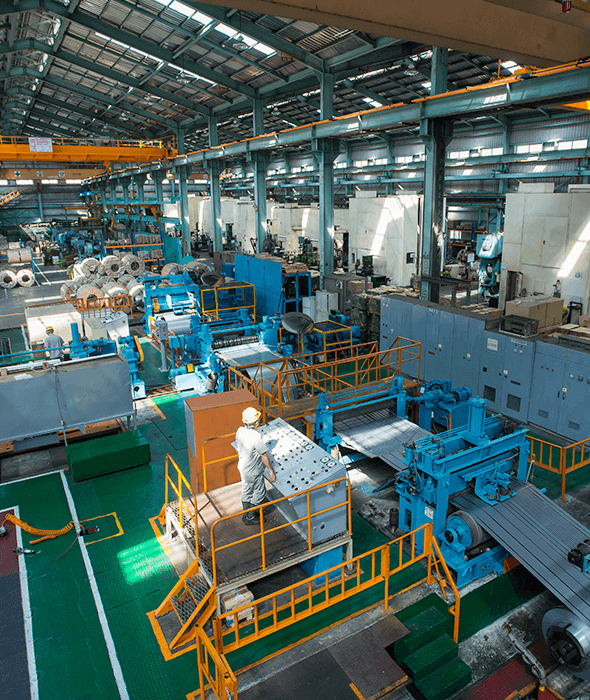

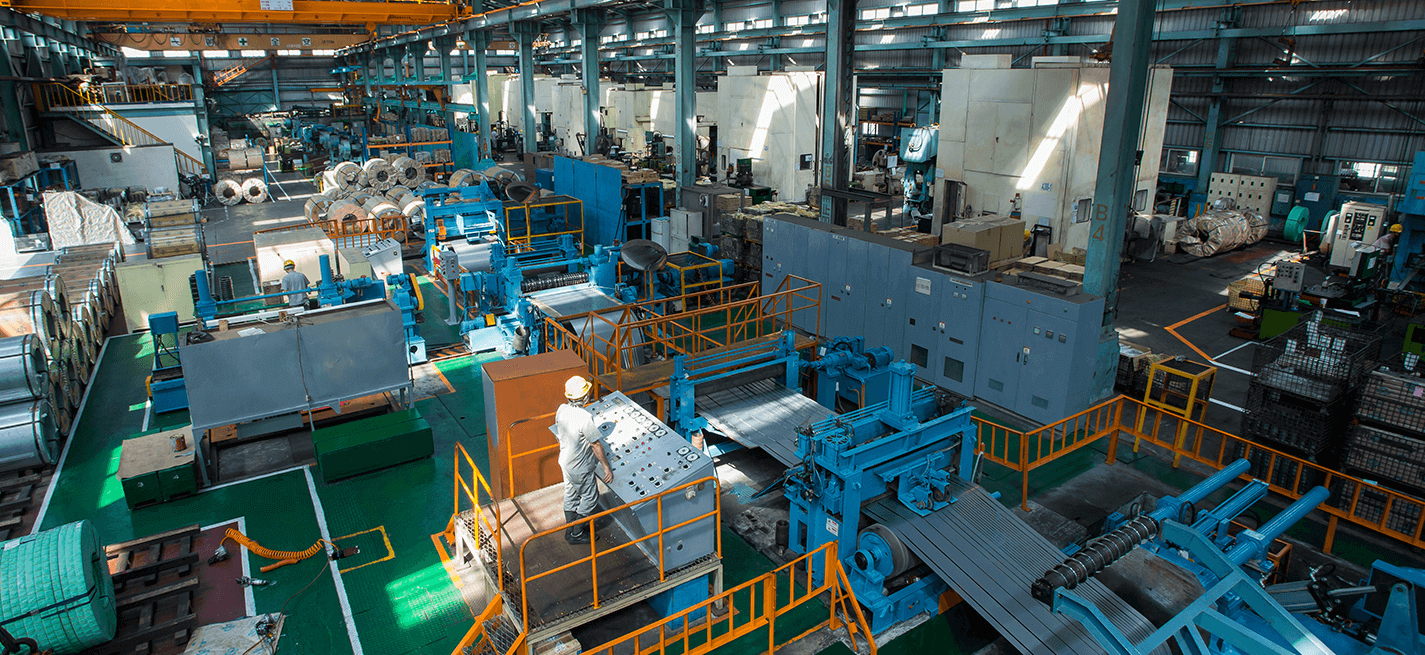

Major equipment: Slitters, annealing furnace, 30MT~300MT AIDA, DOBBY high-speed automatic presses, argon welding machine, precision surface grinder, contact coordinate measuring machine, CNC vertical machining center, CHARMILLES CNC wire cutting EDM machining & NC edm-electrical discharge machine.

Business description

Silicon steel products:

- Types of Silicon Steel Coils: Grain-oriented, non-grain-oriented, ultra-thin, and self-bonding steel coils.

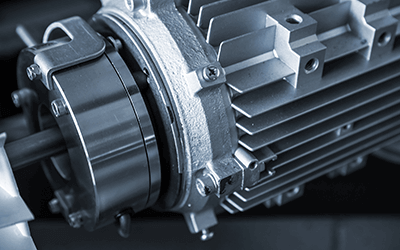

- Laminated Iron Cores: Designed for induction motors, brushed and brushless motors, servo motors, linear motors, stepper motors, permanent magnet motors, and reluctance motors.

- Various Laminated Inductors: Including transformers, ballasts, rectifiers, and filters.

- Application Industries: Power equipment, electric motors, automotive industry, machine tools, household appliances, IT products, communication equipment, and robotics.

Environmental/Occupational Health and Safety management certified to ISO 14001; ISO 45001

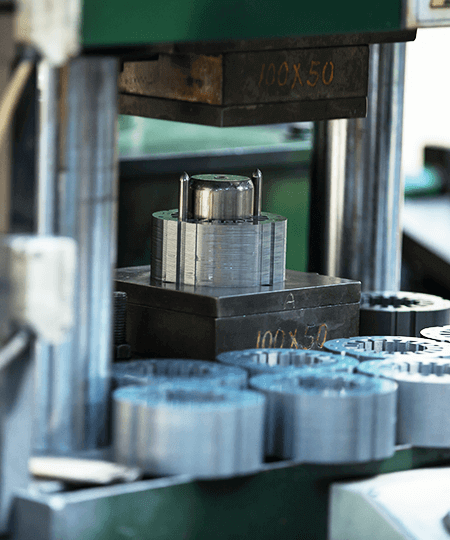

Molds designing and manufacturing:

A professional custom mold design and manufacturing company, offering comprehensive services including requirement analysis, sample cutting, design, manufacturing, testing, acceptance, and technical maintenance. We specialize in the production of stators, rotors, EI cores, and more using continuous stamping dies.

Service Industry

Electrical Steel Division

The main production base of the Electrical Steel Division is in Taichung, engaging in processing of silicon steel rolls (oriented and non-oriented), including slitting, stamping, annealing, riveting, and argon welding. R&D, design, and manufacturing of stamping molds.

The products are applied to the EI iron cores of various converters, ballasts, rectifiers, and the laminated iron cores for stators and rotors of electric motors, power generators, fans, ceiling fans, compressors, and motors for industry, automobile, appliance, and information.

Major production equipment: 4-foot slitting machine, 300-ton stamping press, 200-ton stamping press, 125-ton stamping press, and stamping press under 60 tons. An advanced silicon steel material solution provider in Taiwan, to meet customers’ demands with the full-fledged integrated service manner.

Product and Service

Business bases

Taichung business post

Contact person:Chou, Cheng-Hsiao

Tel. No.: (04)2359-2111 EXT 4126

Fax No.: (04)2359-0911

Address: No. 13, Gongyequ 25th Rd., Nantun Dist., Taichung City

E-mail address: choucs@cysco.url.tw

Lung Tuan business post

Contact person: CHUNG, TAO-MING

KAO, CHI-FU

Tel. No.: (03)489-2131

EXT 3369 (CHUNG, TAO-MING)

EXT 3370 (KAO, CHI-FU)

Fax No.: (03)409-3891

Address: No.236, Bade Sec., Shengting Rd., Longtan Dist, Taoyuan City 32542, Taiwan (R.O.C.)

E-mail address:

CHUNG,TAO-MING - 960039@cysco.url.tw

KAO,CHI-FU - cqt@cysco.url.tw